● Product Name:

Geosynthetic Clay Liner(GCL), GCL/GCLs/Geosynthetics, Clay Liners/Bentonite Liner, Woven/Non-woven Geotextile, GCL Pond Liner/GCL Pond Lining/Bentonite Pond Lining(GCL) Liner, Landfill Liner/Bentonite Waterproofing Pad, Natural Na-bentonite GCL/Na-bentonite GCL, Sodium Bentonite Clay Liner/Geo Clay Liner/HDPE Clay Liners, HDPE Pond Liner/HDPE Geomembrane Liner, Waterproofing Material(GCL)/Waterproofing Products(GCL).

● Weight: 4000g/㎡, 4500g/㎡, 4800g/㎡, 5000g/㎡, 5300g/㎡, 5500g/㎡

● Length: 20m, 30m, 40m, or as required by customer

● Width: up to 6m

● Packing: roll, outer PE plastic membrane or woven fabric

● Delivery Date: 1*40HQ, within 10 days after receiving payment

● MOQ: 1*20GP

● Payment: T/T, L/C

● Production Process of Geosynthetic Clay Liner(GCL):

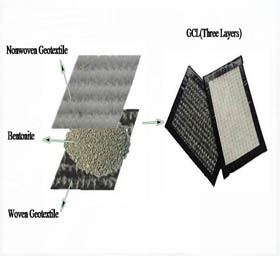

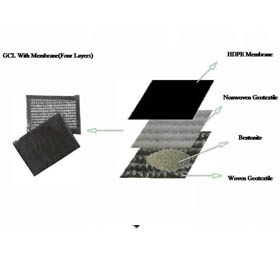

GCL Geosynthetic Clay Liner is made by filling high swelling sodium bentonite between the special composite geotextile fabric, non-woven fabric special needle punched method to lock sodium bentonite into woven fabric in the lower layer by non-woven fabric in the upper layer, thus to provide protection and reinforcement of bentonite. Many small fiber space can be created by needle punched method, when GCL Geosynthetic Clay Liner contacts water and starts to swell, the sodium bentonite can absorb the water weighing six times than its own weight, to prevent bentonite from moving in one direction, thus to form a uniform, high-density coating-shape water-proof layer, to exclude water and waterproof. In order to enhance waterproofing of GCL Geosynthetic Clay Liner, a composite HDPE Geo-membrane is used to cover nonwoven fabric, so this Product is also known as Geosynthetic Clay Liner with HDPE Membrane.

● IAdvantages of Geosynthetic Clay Liner (GCL):

1. Compactness:

Sodium bentonite will form a high density diaphragm about 3mm thick during hydraulic pressure, with permeability for αx10-11 m / sec, equivalent to 100 times than that from 30cm thick clay, with a strong inherent water reservation performance.

2.Permanent waterproof performance:

Since sodium bentonite is a natural inorganic material, there is no aging or corrosion even after a very long time or when surrounding environment changes.

3. Simple and short construction:

Compared with HDPE geomembrane, Geosynthetic Clay Liner, is relatively simple in terms of construction, requiring no heating or paste. Just bentonite powder, nails and washers are enough for connection and fixing. No special inspection is needed after construction, and it's easy to repair if waterproofing defects is detected. So far, it takes shortest time for construction to go with Geosynthetic Clay Liner.

4. Independence from climate:

It's easy for HDPE geomembrane exposed to cold weather to become brittle and broken while Geosynthetic Clay Liner is independent from temperature effects.

5. Integration of Waterproof materials and object:

Reacted with water, sodium bentonite can swell 13-16 times water reaction. Even in the case of vibration and settlement of concrete structure, the bentonite inside the GCL can repair the cracks within 2mm on concrete surface.

6. Envrironmental-friendly:

Bentonite is a natural inorganic and environment-friendly material, producing no toxin or harm to human, and cause no effect on the environment.